How to Tell Which Direction Cable Winder You Need

How to Tell Which Direction Cable Winder You Need

Choosing the correct cable winder direction is critical for smooth spooling, long cable life, and safe lifting. The quick test below makes it easy to confirm whether you need a Right-Hand or Left-Hand winder.

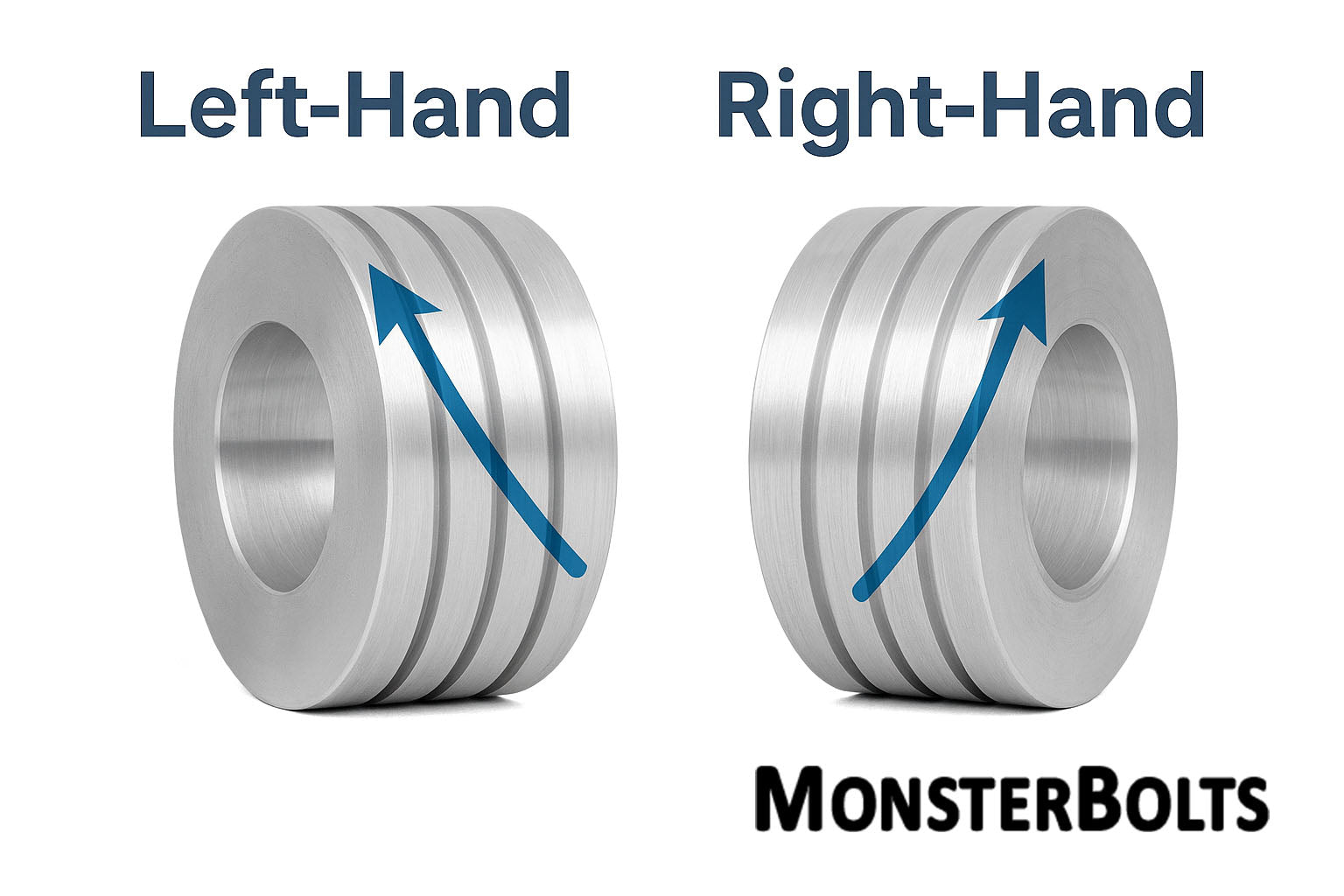

Quick ID Rule: Hold the winder in front of you and look at the groove angle.

• Grooves pointing up and to the right = Right-Hand winder.

• Grooves pointing up and to the left = Left-Hand winder.

Visual Cues at a Glance

| Right-Hand (RH) | Left-Hand (LH) |

|---|---|

| Grooves slant up/right across the face | Grooves slant up/left across the face |

| Trace a groove upward; it moves right | Trace a groove upward; it moves left |

| Matches drive-pipe rotation that feeds cable to the right | Matches drive-pipe rotation that feeds cable to the left |

3-Step Check (Takes 10 Seconds)

- Hold the winder directly in front of you, facing the grooves.

- Find one groove near the center and follow it upward with your eye.

- Note the slope: Up/right = Right-Hand. Up/left = Left-Hand.

Why Direction Matters

- Smooth Spooling: Correct direction builds neat, even layers without crossing.

- Longer Cable Life: Minimizes flattening, kinks, and abrasion on 7×19 cable.

- Safety & Reliability: Prevents binding and uneven lifting loads.

- Less Maintenance: Fewer adjustments and premature cable replacements.

Shop the Winder You Need

Right-Hand 2-3/8″ Cable Winder

CNC-machined 6061-T6 aluminum. For side-mounted drive pipes.

View Right-HandLeft-Hand 2-3/8″ Cable Winder

CNC-machined 6061-T6 aluminum. For side-mounted drive pipes.

View Left-HandCable Winder FAQs

How do I quickly identify Right vs Left?

Face the grooves. If they angle up/right, it’s Right-Hand. If they angle up/left, it’s Left-Hand.

Does the boat-lift side (left/right) determine the winder?

Not by itself. Match the winder’s groove direction to your drive-pipe rotation and cable feed path. Check your motor’s rotation arrow or run a brief test (without load) to verify.

What happens if I install the wrong hand?

The cable can cross, stack unevenly, or rub the flange. Stop and swap to the correct hand to prevent damage.

What sizes and capacities are typical?

Our 2-3/8″ OD winders are designed around 7×19 aircraft cable up to 5/16″ diameter with roughly ~36 wraps (~24 ft), depending on setup.

Solid vs Split winder — which should I choose?

Solid slides onto the pipe before assembly. Split bolts around an existing pipe — great for retrofits and service work.

Is mounting hardware included?

Hardware is sold separately. Typical setup uses one 5/8″-11 × 3-1/4″ stainless bolt for the cable anchor and two 5/16″-18 × 2-3/4″ stainless bolts with lock washers & nuts for the winder.

Where are Monster Bolts winders made?

Proudly Made in the USA and precision-machined in Florida.

Important: Installing a winder slightly increases the effective drive-pipe diameter. Verify motor & hoist ratings to confirm lift capacity after installation.

More Monster Products

Building a complete solution? Explore our full Machined Hardware collection and shop cable-rigging fasteners.

Order with Confidence

Every Monster Bolts order ships fast from Florida and is backed by our commitment to quality and customer satisfaction. Not sure which hand you need? Contact us — we’ll help you choose the right part.