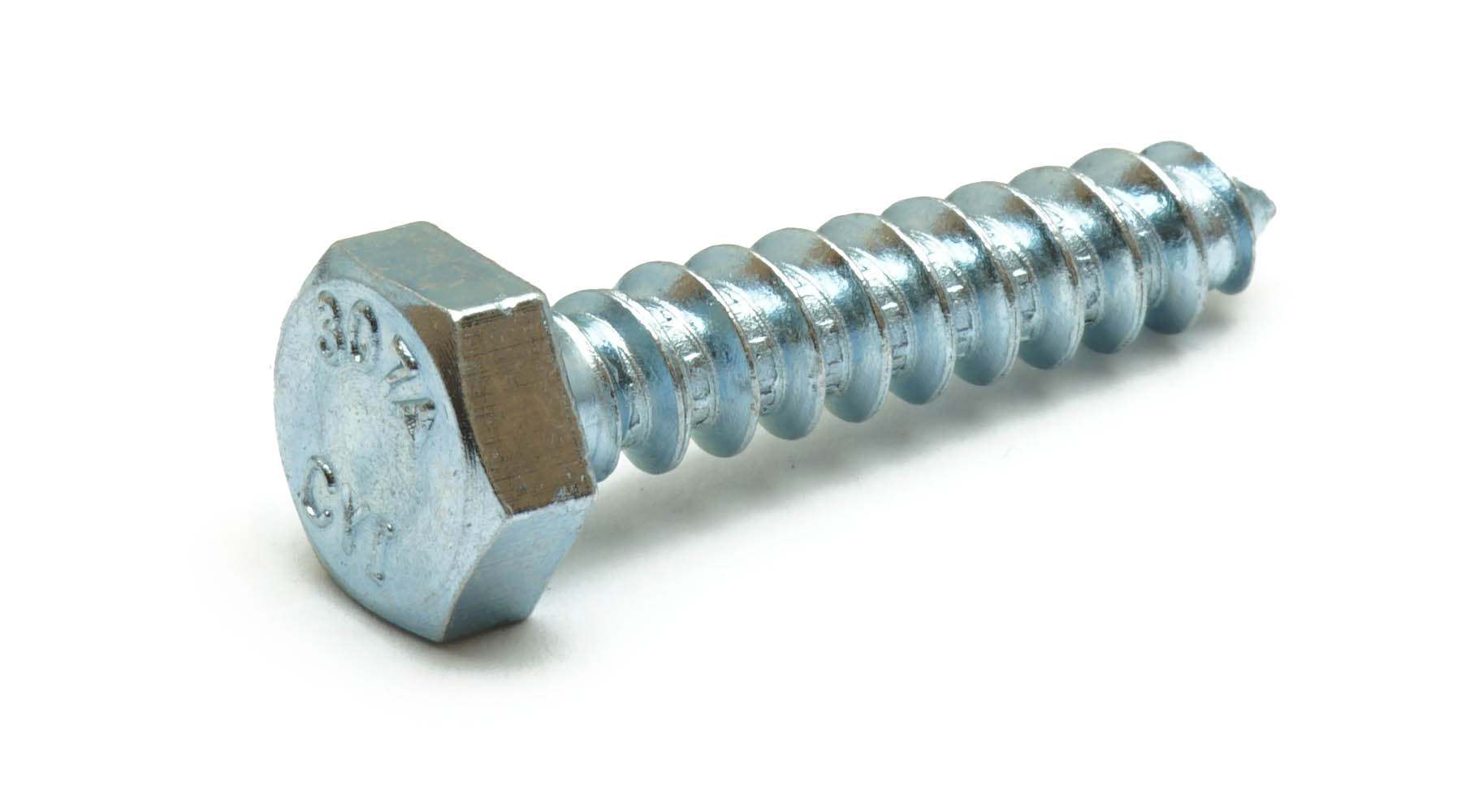

Lag Bolts (Lag Screws): What They Are, How Much They Hold, and How to Use Them

Common Uses for Lag Bolts

- Roof beams and heavy timber connections

- Garage pillars / posts

- TV wall mounting into wood studs*

- Decks, pergolas, heavy fixtures

*TV mounts typically ship with specific hardware; always follow the mount manufacturer’s instructions and verify stud locations.

How Lag Screws Work

Lag screws have a sharp gimlet point and coarse threads that bite into wood. Because of their diameter, a pilot hole is required. For maximum strength, embed threads into side grain (not end grain) and keep the screw centered in the member’s middle third.

Lag Screw Strength & Example Capacities

Shear and withdrawal (pull-out) depend on wood species, embedment depth, spacing/edge distances, and load direction. Use engineering references and calculators for precise design. The following examples are illustrative:

Illustrative Shear (embedment noted)

- 1/4″ @ 2.0″ embed ≈ 272 lb shear

- 5/16″ @ 2.5″ embed ≈ 368 lb shear

- 3/8″ @ 3.0″ embed ≈ 432 lb shear

- 1/2″ @ 3.0″ embed ≈ 624 lb shear

Values vary by species, condition, and detailing; verify with the references below.

Withdrawal (Pull-Out) Example

5/16″ lag screw: approx. ~205–307 lb/in of threaded embedment (species-dependent). More embedment = more capacity.

Threads should engage side grain and be located in the middle third of the member width.

References: American Wood Council resources and calculators provide design values, adjustment factors, and detailing rules.

Pilot Holes & Installation

Pilot & Prep

- Pilot diameter: Follow species-specific pilot guidance (hardwoods vs softwoods). Too small = splitting/over-torque; too large = low holding power.

- Depth: Drill at least to anticipated threaded embedment; clear chips.

- Location: Center of the stud/post; maintain edge and end distances per code.

Driving & Torque

- Install with an impact driver or wrench; finish by hand to avoid over-torque and head snap.

- Use washers under the head to spread load and protect the surface when required.

- For exterior use, choose hot-dipped galvanized or stainless lag screws to resist corrosion.

Quick Pilot Hole Chart (Most Situations)

Before using a lag bolt in a wood stud, the hole must be pre-drilled to avoid splitting and minimize the chance of breaking the head.

| Lag Bolt Size | Pilot Hole Size |

|---|---|

| 1/4" | 5/32" |

| 5/16" | 3/16" |

| 3/8" | 15/64" |

| 1/2" | 5/16" |

| 5/8" | 13/32" |

| 3/4" | 1/2" |

Pilot Hole Sizes by Wood Group

Variables such as wood type, bolt length, and bolt diameter all factor into ideal pilot sizes. Wood types are grouped by the American Lumber Standard Committee (ALSC): Soft Wood (Groups 3–4), Medium Wood (Group 2), Hard Wood (Group 1). Many newer U.S. homes use studs of Spruce (Group 3–4) or Douglas Fir (Group 2–3).

| Lag Bolt Size | Pilot Hole Size | ||

|---|---|---|---|

| Soft Wood* | Medium Wood* | Hard Wood* | |

| 1/4" | 3/32" | 5/32" | 3/16" |

| 5/16" | 9/64" | 3/16" | 13/64" |

| 3/8" | 11/64" | 15/64" | 1/4" |

| 1/2" | 15/64" | 5/16" | 11/32" |

| 5/8" | 5/16" | 13/32" | 29/64" |

| 3/4" | 13/32" | 1/2" | 9/16" |

- Soft Wood (Group 3–4), Medium Wood (Group 2), Hard Wood (Group 1). Consult an engineer for questions regarding specific applications.

How to Remove a Lag Bolt with a Broken Head

- Mark center with a punch to keep the bit from wandering.

- Drill a small pilot. Use a left-handed bit or extraction bit at low speed in reverse.

- If it backs out, continue carefully. If not, enlarge as needed and use an extractor, or grip exposed threads with locking pliers.

Frequently Asked Questions

Are lag bolts structural?

Lag screws are used in structural applications when sized and detailed per code/engineering (species, spacing, edge distances, embedment, etc.). Always verify with local code officials or a design professional.

Are lag bolts the same as wood screws?

Lag screws are a type of wood screw—larger diameter with a hex head for high torque and heavy-duty use.

Do lag bolts self-tap?

No. They require a pilot hole. The gimlet point helps start, but a pilot is necessary for proper performance.

Can I use lag bolts in concrete or brick?

Not directly. For masonry, use anchors designed for concrete/brick (e.g., wedge, sleeve, or lag shields). You can thread a lag into an appropriate lag shield anchor in masonry.

What size lag bolts for a 2×6?

Depends on the load and detailing. A common starting point is 3/8″ diameter with sufficient length to achieve the required embedment, but you must verify with code/engineering and the AWC calculator.

Outdoor use—what coating?

Hot-dipped galvanized or stainless (18-8 or 316 for coastal) to resist corrosion.

Typical tensile strengths?

Carbon steel around ~60,000 psi minimum; 18-8 stainless around ~100,000 psi minimum, depending on product specs. Always check the listing.

Shop Lag Screws

Need help choosing? Call (850) 764-2658 or email support@MonsterBolts.com — we’re happy to help.

*The example capacities above are simplified to illustrate concepts only. For any structural or safety-critical connection, use code-approved design methods, verify species and detailing, and follow manufacturer instructions.

Quick Answer:

Quick Answer:

2 comments

Donad Terwilliger

Where can I get 3/8 5 inch length black lag bolts 50 per box and the best price

Jennifer Reinhardt

Hello,

I work for a small fabrication shop in Washington state, USA and I’m looking for a vendor that could supply me with 2 lag screw sizes, I am looking for the following. Let me know if you can provide with pricing and lead time.

3/8” x 5” Fully Threaded Galvanized 307A Lag Screws-10,000ea.

5/8” x 5” Fully Threaded Galvanized 307A Lag Screws-10,000ea.