Thread galling is a common but frustrating problem when working with stainless steel, titanium, and aluminum fasteners. It happens when friction and adhesion cause metal from one surface to transfer to another. This “cold welding” effect can seize threads permanently, leaving cutting or splitting as the only way to remove the bolt or nut.

Why Does Galling Happen?

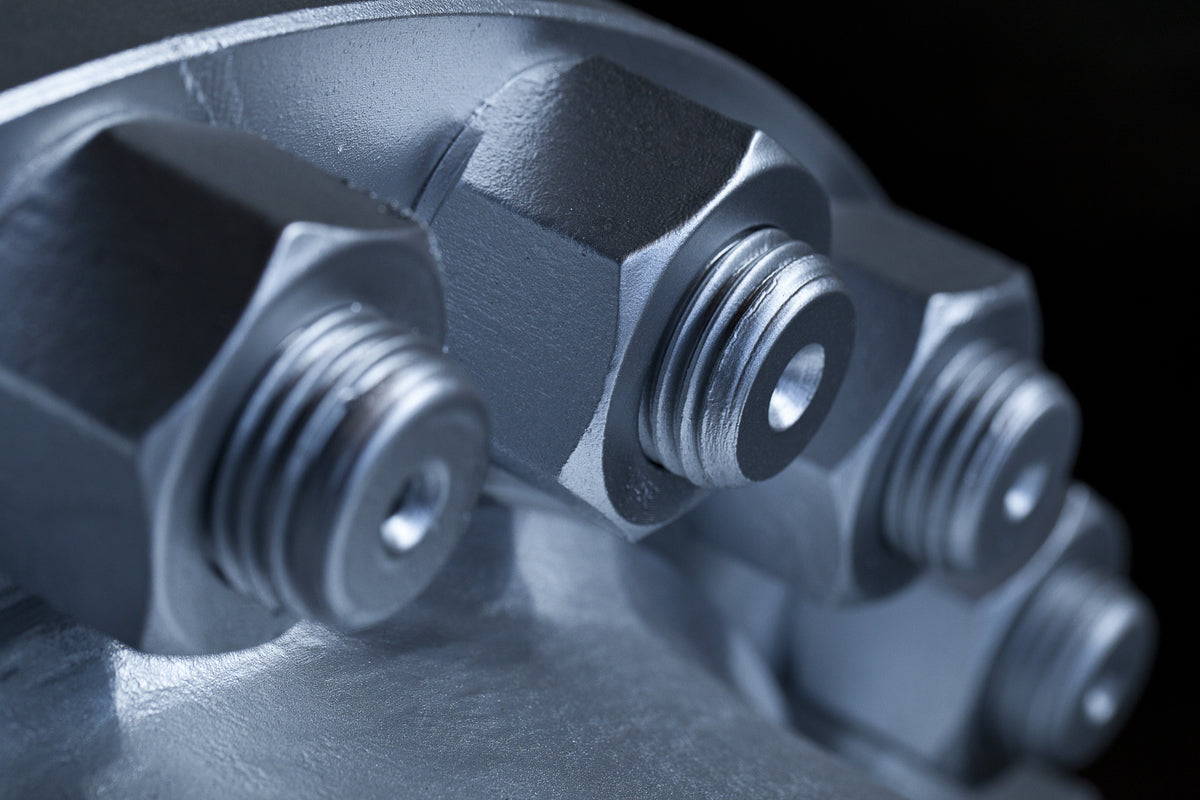

Fastener threads have tiny high points designed for gripping. During tightening, these points slide against each other under pressure. If the friction is too high, the surfaces weld together, creating lumps that lock the fastener in place.

The softer and more ductile the material, the more prone it is to galling. That’s why stainless steel and titanium fasteners, despite their corrosion resistance, are more vulnerable than hardened steel.

Fasteners Most Susceptible to Galling

- Stainless steel: A2/304 and A4/316 are especially prone without lubrication.

- Titanium: Prone due to high reactivity and ductility.

- Aluminum: Softer alloys can bind easily under pressure.

- Fine-thread bolts: More surface contact means more opportunity for friction and cold welding.

Tips to Prevent Thread Galling

1. Slow Down

High-speed installation generates heat, which accelerates galling. Avoid power tools for stainless and titanium fasteners. Instead, use controlled hand or low-RPM torque tools.

2. Don’t Use Bolts to Pull Joints Together

This is one of the most common and easily preventable causes of galling. A bolt’s job is to clamp, not to draw parts into alignment. For example, if you’re working with bowed lumber or slightly misaligned steel, forcing the bolt to pull the materials into position puts enormous stress on the threads. This extra friction is a perfect recipe for galling and seized fasteners.

Instead, pre-position materials or use clamps to hold pieces securely before tightening bolts. The bolt should only apply tension to maintain the joint, not act as the muscle to move warped parts. This small step eliminates one of the biggest risks of galling and extends the life of both the fastener and the material you’re working on.

3. Use Lubrication

Thread lubricants (anti-seize, wax-based, or moly lube) dramatically reduce friction. This makes the sliding action smoother, reduces heat, and prevents cold welding.

4. Inspect Threads Before Use

Never use fasteners with dirty, dented, or damaged threads. A nut should spin freely onto a bolt by hand. If it doesn’t, stop—forcing it will increase friction and risk galling.

Practical Takeaway

Thread galling isn’t inevitable. With slower installation, proper joint preparation, lubrication, and high-quality fasteners, you can avoid it entirely. At Monster Bolts, we supply stainless steel, alloy, and titanium fasteners backed by technical guidance, so your projects go smoothly the first time.

Thread Galling FAQs

What is thread galling?

Thread galling is a type of cold welding where friction and pressure cause fastener threads to seize together, usually during installation.

Which fasteners are most prone to galling?

Stainless steel, titanium, and aluminum fasteners are the most prone, especially when fine-threaded or installed too quickly without lubrication.

How can I prevent galling?

Use anti-seize lubricants, slow installation speeds, clamps to align joints before tightening, and inspect threads before use.

What should I do if galling occurs?

Once threads seize, the only solutions are cutting the bolt or splitting the nut. Prevention is far easier than repair.