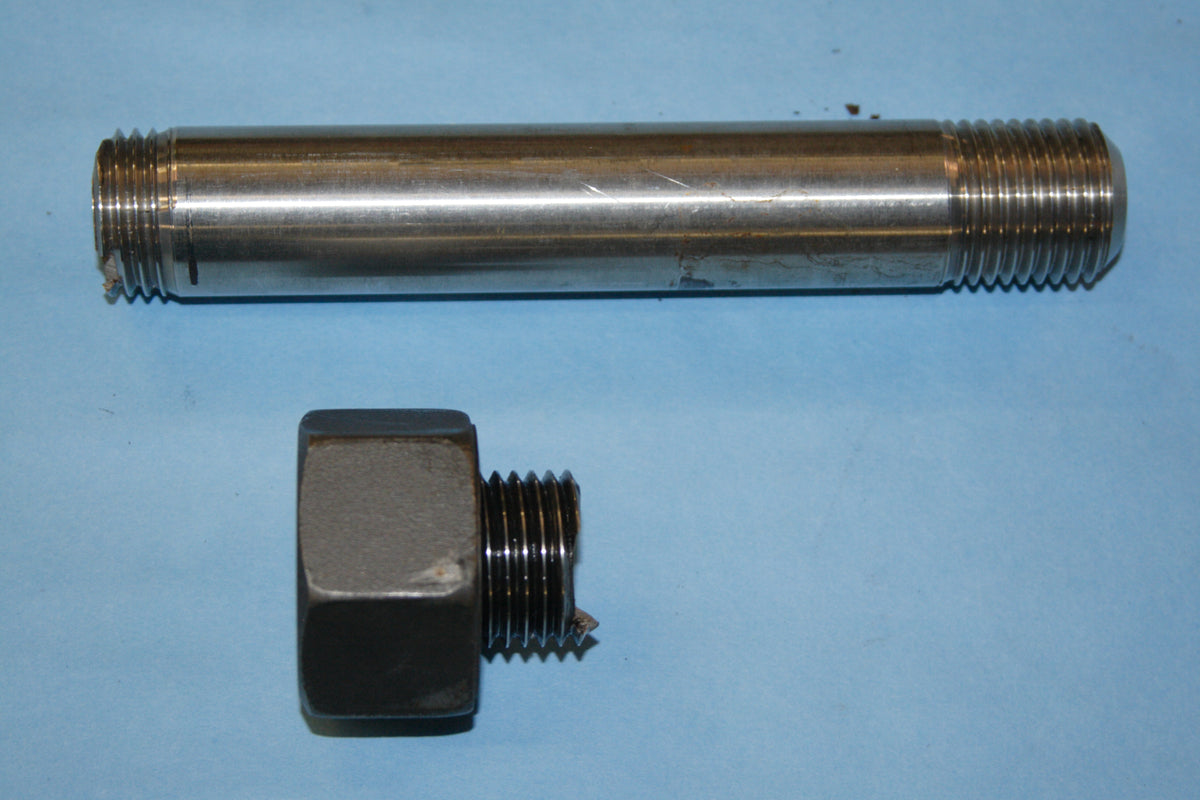

Stainless steel is durable and corrosion-resistant — but it can “grab” under load. If you’ve ever had a nut lock solid on a bolt, you’ve met thread galling (also called cold welding, seized threads, or a frozen bolt). Here’s how to avoid it and what to do if it happens.

What is thread galling?

Galling is adhesive wear between metal threads. Under pressure and friction, peaks on the mating threads shear and transfer material. The surfaces “weld” microscopically — the joint tightens abruptly, heat spikes, and the fastener seizes.

Why stainless steels are prone to seizing

- Work-hardening & ductility: Austenitic grades (e.g., A2/A4) smear and cold weld easily under friction.

- Clean, oxide-free contact: Stainless tends to have low-friction films removed during tightening, increasing metal-to-metal contact.

- High friction events: Dry threads, high speed tools, misalignment, and using bolts to “pull parts together” all raise risk.

Common symptoms (catch it early)

- Torque climbs suddenly and feels “gritty”.

- Socket strains but the nut doesn’t advance — it feels frozen.

- Back-off is impossible; forcing it may shear the bolt or split the nut.

How to prevent galling (the playbook)

- Lubricate threads. Use an anti-seize suitable for stainless (nickel, moly, ceramic, or food-grade where required). Coat lightly on the male thread and under the nut face/washer. Recalculate torque: lubrication reduces friction, so the same torque yields higher preload.

- Slow the install. Avoid high-speed drivers on stainless. If you use power tools, run them slow and finish by hand. Heat drives adhesion.

- Align parts first — don’t pull joints together with bolts. Bolts are for clamping, not for drawing parts into alignment. Pre-position parts, use clamps/straps/prybars to close gaps, then install fasteners. For bowed lumber, warped brackets, or flange gaps, close the joint mechanically before tightening to avoid side-loading and friction spikes.

- Use the right hardware. Prefer coarse pitch where possible (fine threads have more surface engagement). Use proper nuts (A2/A4 with matched class), and consider hardened washers to reduce under-head friction.

- Clean, undamaged threads. Replace dinged, dirty, or previously seized components. Hand-start to ensure no cross-threading.

- Follow torque guidance. Use a torque wrench; verify specs on the drawing. See our socket screw torque chart.

If a fastener starts to seize: what to do

- Stop immediately. Back off a quarter turn. If it won’t back off, don’t force it.

- Cool and re-lube. Let it cool. Apply penetrating oil/anti-seize and try gradual back-and-forth motion.

- Last resorts. Split the nut, cut the bolt, or drill out. Rebuild the joint with fresh hardware and lubrication.

Myths & misconceptions

- “Stainless won’t seize if it’s new.” New stainless can seize on the first install if it’s dry, fast, or misaligned.

- “More torque = more secure.” Over-torque overheats threads and increases seizure risk.

- “WD-40 is anti-seize.” It’s not. Use a true anti-seize compound rated for stainless.

Quick checklist

- ✅ Light anti-seize on threads and under the nut/washer

- ✅ Align and clamp parts before tightening

- ✅ Slow installation; finish by hand

- ✅ Clean, undamaged, matched stainless hardware

- ✅ Use specified torque (adjust if lubricated)

FAQs

Is “seized” or “frozen” the same as thread galling?

Yes. Those terms describe the same failure mode: stainless threads cold-weld during tightening and lock solid.

What’s the best lube for stainless threads?

An anti-seize compound rated for stainless (nickel, moly, ceramic, or food-grade as required). Apply a thin, even coat to threads and under the nut face/washer.

Do I need hermetic seals or just environmental protection?

For most marine/outdoor projects, environmental sealing (IP67/IP68) is sufficient. Hermetic sealing is for vacuum/pressure-critical applications like aerospace. See our guide on Hermetic vs Environmental Seals.

Will slower installation really help?

Yes. Heat and friction are primary drivers. Slowing the driver and finishing by hand reduce heat and lower the chance of seizing.

Can I reuse hardware that has started to gall?

No. Replace any fastener that showed signs of seizing. Inspect mating threads; clean or replace as needed.