Description

Steel Nylon Insert Lock Nuts with Black Oxide Coating

Vibration-Resistant – Prevailing Torque Type

Our Steel Nylon Insert Lock Nuts with Black Oxide Coating are especially useful in situations involving vibration. These prevailing torque lock nuts feature a nylon collar insert that increases friction on the screw thread, providing a secure and vibration-resistant fastening solution. The black oxide finish offers a sleek appearance suitable for various applications.

Why Choose Our Steel Nylon Insert Lock Nuts?

- Vibration Resistance: Nylon insert prevents loosening due to vibration and movement.

- Secure Locking Mechanism: Elastic deformation of the nylon collar ensures a tight fit without damaging the threads.

- Sleek Appearance: Black oxide coating provides a professional look.

- Durable Performance: Designed for reliable use in various applications.

- Easy Installation: Standard hex design allows for easy tightening with standard tools.

Important Note

NOTE: Sizes 1/4"-20 and 1/4"-28 nuts have a Black Phosphate and Oil finish instead of Black Oxide.

Ideal Applications

- Automotive and Motorcycle Assembly

- Industrial Machinery

- Electronics and Equipment

- Furniture and Cabinetry

- Applications with Vibration

Available Sizes

We offer a range of sizes to suit your specific needs:

- #2-56

- #4-40

- #6-32

- #8-32

- #10-24

- #10-32

- 1/4"-20 (Black Phosphate and Oil finish)

- 1/4"-28 (Black Phosphate and Oil finish)

Note: Nut size corresponds to the screw or bolt size it fits (e.g., a 1/4"-20 nut fits a 1/4"-20 screw).

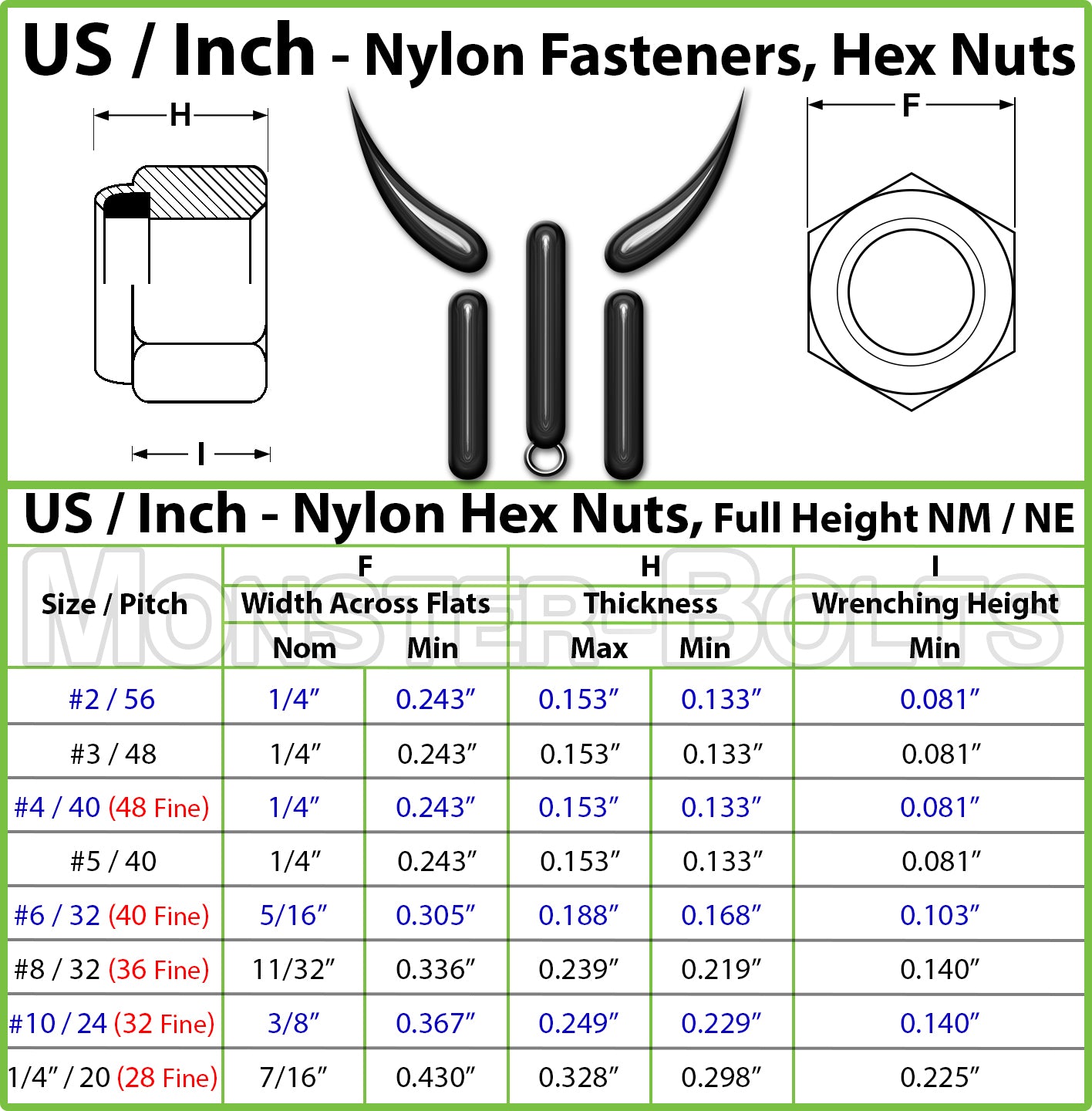

Detailed Specifications

- Material: Carbon Steel

- Finish: Black Oxide Coating (1/4"-20 and 1/4"-28 sizes have Black Phosphate and Oil finish)

- Locking Mechanism: Nylon Insert

- Thread Type: UNC (Unified National Coarse) and UNF (Unified National Fine) Threads

- Nut Type: Nylon Insert Lock Nut (Nylock Nut)

- System of Measurement: Inch (Imperial / US)

- Standards Met: ASME B18.16.6

How Do Nylon Insert Lock Nuts Work?

The nylon collar insert is placed at the end of the nut, with an inner diameter slightly smaller than the major diameter of the screw. When the nut is tightened, the threads engage with the nylon insert, which deforms elastically over the threads. This deformation increases friction and creates a prevailing torque that resists loosening due to vibration.

Material Properties

Our steel nylon insert lock nuts with black oxide coating offer:

- Strength and Durability: Carbon steel construction provides reliable performance.

- Vibration Resistance: Nylon insert ensures a secure hold even in high-vibration environments.

- Sleek Appearance: Black oxide finish offers a professional look for exposed applications.

- Temperature Limitations: Suitable for applications up to 250°F (121°C) due to nylon insert limitations.

Installation Tips

For optimal performance when using steel nylon insert lock nuts:

- Ensure the nut size matches the bolt or screw size.

- Thread the nut onto the bolt by hand to avoid cross-threading.

- Tighten using the appropriate wrench or socket for the hex size.

- Avoid over-tightening to prevent stripping threads or damaging the nylon insert.

- Do not reuse nylon insert lock nuts; replace them if removed.

- Not recommended for high-temperature applications exceeding 250°F (121°C).

Order Yours Today

Ensure secure fastening in vibration-prone environments with our reliable Steel Nylon Insert Lock Nuts with Black Oxide Coating. Ideal for applications requiring a strong, vibration-resistant fastening solution. Order now and enjoy fast shipping and exceptional customer service!

✔️ Trusted by professionals in automotive, industrial, and construction sectors

✔️ High-quality carbon steel for strength and reliability

✔️ Wide range of sizes to fit your needs

Need assistance? Contact our support team | Shipping and Return Policy